焊接專機重要且常用到的兩大分類

來源:http://m.gouteli.cn/ 發(fā)布時間:2023-01-12 瀏覽次數(shù):0

焊接專機是用于自動化生產(chǎn)的,要求人工或者機械手上下工件,焊接工裝夾具自動將工件固定,定位,自動啟動焊接電源的電弧,自動送絲和焊槍或工件的自動移動,焊接完成后自動退回,人工或機械手取下工件。下面來講講山東焊接專機主要有的兩種分類。

The special welding machine is used for automatic production. It requires manual or mechanical hands to mount and dismount the workpiece. The welding fixture will automatically fix and position the workpiece, automatically start the arc of the welding power supply, automatically feed the wire and automatically move the welding gun or workpiece, automatically return after welding, and manually or mechanically remove the workpiece. Next, we will talk about two main types of Shandong special welding machines.

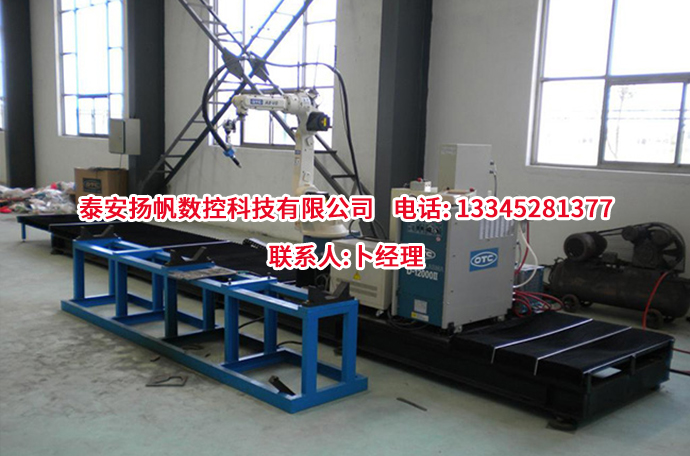

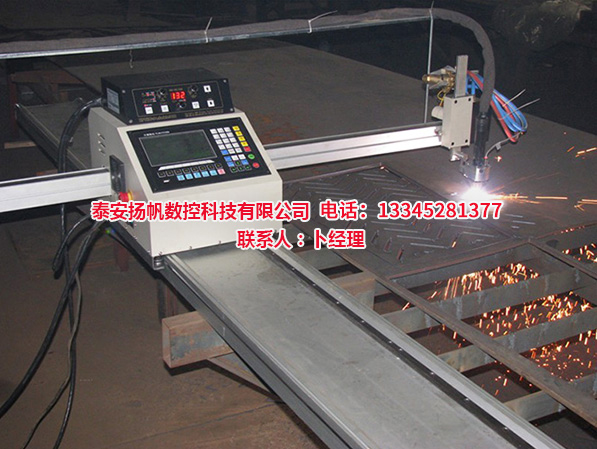

自適應(yīng)控制自動化焊接專機

Self-adaptive control automatic welding machine

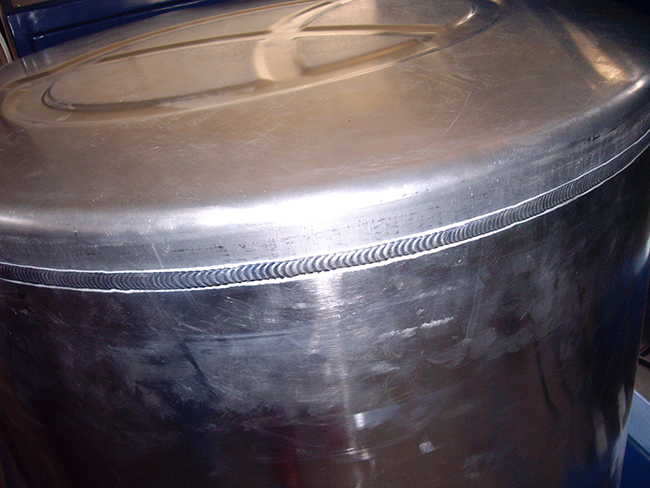

該類專機是一種自動化程度較高的焊接設(shè)備。它配備傳感器和電子檢測線路,對焊縫的軌跡自動導(dǎo)向和跟蹤,有的設(shè)備還可以對焊接參數(shù)如焊接電流、焊接電壓、焊接速度等實現(xiàn)閉環(huán)控制,整個焊接過程按預(yù)先設(shè)置的程序和工藝參數(shù)自動完成。

This kind of special machine is a welding equipment with high degree of automation. It is equipped with sensors and electronic detection circuits to automatically guide and track the weld track. Some equipment can also realize closed-loop control of welding parameters such as welding current, welding voltage, welding speed, etc. The whole welding process is automatically completed according to preset procedures and process parameters.

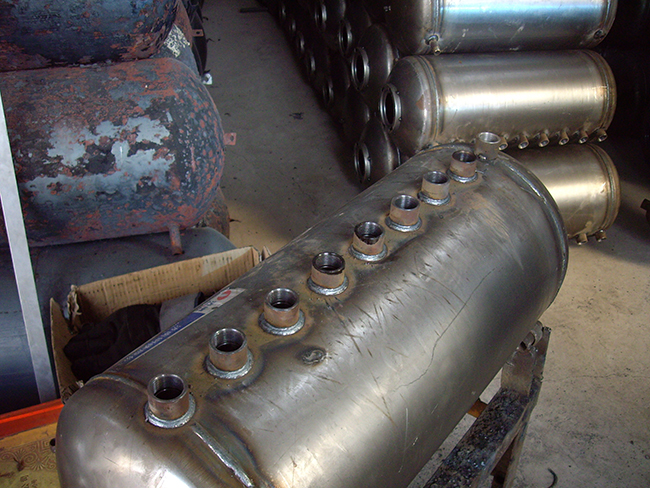

比如,大一點的筒體或管類零件,管道預(yù)置焊接專機要保證工件的一致性和達到很高的配合精度是非常困難的,需要花費更大的成本。該焊接專機采用了弧長跟蹤器和焊槍擺動器。由于工件表面的凹凸不平,需要焊槍隨著工件表面的高低不平,需要進行上下運動,以保持焊槍與工件表面的距離一致,從而保證電弧的穩(wěn)定性。

For example, it is very difficult to ensure the consistency of the workpiece and achieve a high fitting accuracy of the pipe preset welding machine for larger cylinder or pipe parts, which requires a higher cost. The special welding machine adopts arc length tracker and welding gun swinging device. Due to the unevenness of the workpiece surface, the welding gun needs to move up and down along with the unevenness of the workpiece surface to keep the distance between the welding gun and the workpiece surface consistent, so as to ensure the stability of the arc.

同時可以自動實現(xiàn)多層焊接。若焊接兩層,當焊接完一周后,跟蹤器檢測到表面高度增加,則可以自動將焊槍提高。

At the same time, multi-layer welding can be realized automatically. If two layers are welded, after one week of welding, the tracker detects that the surface height increases, and the welding gun can be automatically raised.

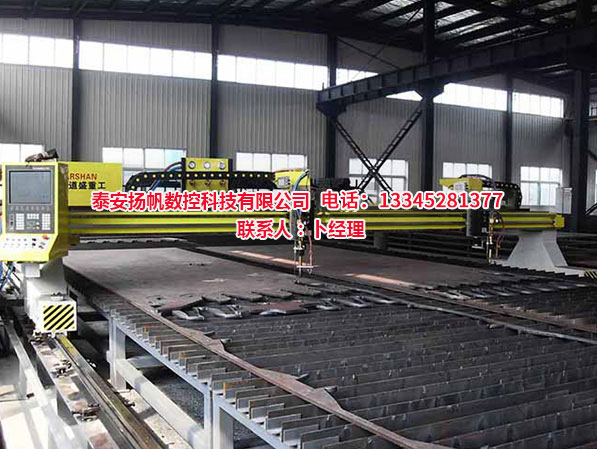

智能化自動焊接設(shè)備

Intelligent automatic welding equipment

它利用各類傳感元件,如視覺傳感器、觸角傳感器、光敏傳感器等,并借助計算機軟件系統(tǒng)、數(shù)據(jù)庫、系統(tǒng)而具有識別、判斷、實時檢測、運算、自動編程、焊接參數(shù)調(diào)用等,操作人員只需在人機界面上輸入材料的牌號、板厚、坡口形式、焊絲牌號和直徑、焊劑或保護氣體種類等,焊接工藝參數(shù)自動生成或調(diào)用相應(yīng)參數(shù)。

It makes use of various sensing elements, such as visual sensors, feeler sensors, photosensitive sensors, etc., and with the help of computer software systems, databases, expert systems, it has the functions of identification, judgment, real-time detection, calculation, automatic programming, welding parameter call, etc. The operator only needs to input the material grade, plate thickness, groove form, wire grade and diameter, flux or shielding gas type, etc. on the human-machine interface, The welding process parameters are automatically generated or called.

即可完成全自動焊接。由于這類設(shè)備成本非常高,實際影響焊接質(zhì)量的因素很多,比如氣體的純度,流量,焊接電流,電壓,電源輸入的波動,工件的水汽或銹蝕、焊縫的寬窄,焊縫的高低等等,所以很難完成智能化焊接,在實際生產(chǎn)中很少用到。

The full automatic welding can be completed. Because the cost of such equipment is very high, and there are many factors that actually affect the welding quality, such as the purity of gas, flow, welding current, voltage, fluctuation of power input, moisture or corrosion of workpiece, width of weld, height of weld, etc., it is difficult to complete intelligent welding, which is rarely used in actual production.

焊接專機是為特定的工件和一定形狀的焊接接頭而專門設(shè)計的焊接自動化設(shè)備,當然在使用期間不可避免會存在一些問題,這就要求操作人員做好相關(guān)的檢查事項了,預(yù)防是關(guān)鍵。更多相關(guān)內(nèi)容就來我們網(wǎng)站http://m.gouteli.cn咨詢吧!

The special welding machine is a welding automation equipment specially designed for a specific workpiece and a certain shape of welding joint. Of course, there will inevitably be some problems during use, which requires the operator to do a good job in relevant inspection items, and prevention is the key. Come to our website for more relevant content http://m.gouteli.cn Ask!