自動(dòng)焊接專機(jī)日常保養(yǎng)八大事項(xiàng)

來源:http://m.gouteli.cn/ 發(fā)布時(shí)間:2022-09-08 瀏覽次數(shù):0

如今隨著智能化、自動(dòng)化技術(shù)、電子信息技術(shù)、機(jī)械結(jié)構(gòu)設(shè)計(jì)技術(shù)性的發(fā)展趨勢,及其我們對(duì)設(shè)備的品質(zhì)規(guī)定的提升,焊接品質(zhì)、美觀大方度等獲得了很大的高度重視。下面山東焊接專機(jī)廠家來講講自動(dòng)焊接專機(jī)日常保養(yǎng)八大事項(xiàng)。

Nowadays, with the development trend of intelligence, automation technology, electronic information technology, and the technicality of mechanical structure design, as well as the improvement of our quality requirements for equipment, welding quality and aesthetics have been highly valued. Next, Shandong welding machine manufacturers will talk about the eight items of daily maintenance of automatic welding machines.

1.焊接操作機(jī)中傳動(dòng)鏈條為零配件,每一年需拆下來查驗(yàn)一次,妥善處理。

1. The drive chain in the welding operation machine is a spare part, which needs to be removed for inspection every year and properly handled.

2.各限位開關(guān)的姿勢協(xié)調(diào)能力、穩(wěn)定性要時(shí)常查驗(yàn),以防有松脫、毀壞。

2. The posture coordination ability and stability of each limit switch shall be checked frequently to prevent loosening and damage.

3.電源電路連接頭要時(shí)常查驗(yàn),維持聯(lián)接堅(jiān)固,接插靠譜。

3. The power circuit connector should be checked frequently to ensure that the connection is firm and reliable.

4.工作平臺(tái)控制板及手操器內(nèi)的灰塵要三個(gè)月一次用空氣壓縮吹。

4. The dust in the control board of the working platform and the manual operator should be compressed and blown once every three months.

5.電器、旋紐、電源開關(guān)要時(shí)常查驗(yàn),保持干凈和較好的觸碰,以防錯(cuò)誤操作。

5. Electrical appliances, knobs and power switches shall be inspected frequently, kept clean and well touched to prevent wrong operation.

6.各滑軌、滑架、滾珠絲杠及螺帽等運(yùn)動(dòng)部位常常檢測處理,避免灰塵沉積而危害運(yùn)動(dòng)部位的靈便運(yùn)動(dòng)。

6. The moving parts such as sliding rails, carriages, ball screws and nuts are often detected and treated to avoid dust deposition and endangering the convenient movement of the moving parts.

7.各滾動(dòng)直線導(dǎo)軌的接觸面不允許撞擊、損壞。滾珠絲杠、蝸桿等重要運(yùn)動(dòng)構(gòu)件要時(shí)常查驗(yàn)防止損壞狀況。

7. The contact surface of each rolling linear guide shall not be impacted or damaged. Ball screw, worm and other important moving components should be inspected frequently to prevent damage.

8.自動(dòng)焊接焊接操作機(jī)各運(yùn)動(dòng)部位、滑軌與滾軸該涂潤滑油脂,閉試傳動(dòng)系統(tǒng)部位應(yīng)注潤滑脂,以維持構(gòu)件運(yùn)動(dòng)靈便;關(guān)鍵是對(duì)平心輪、齒條構(gòu)件的維護(hù)保養(yǎng),確保其擰緊,保證橫臂運(yùn)動(dòng)豎直。

8. All moving parts, sliding rails and rollers of the automatic welding and welding operator shall be coated with lubricating grease, and the transmission system of the closed test shall be filled with lubricating grease to maintain the flexibility of component movement; The key is to maintain the flat wheel and rack components, ensure that they are tightened, and ensure that the cross arm moves vertically.

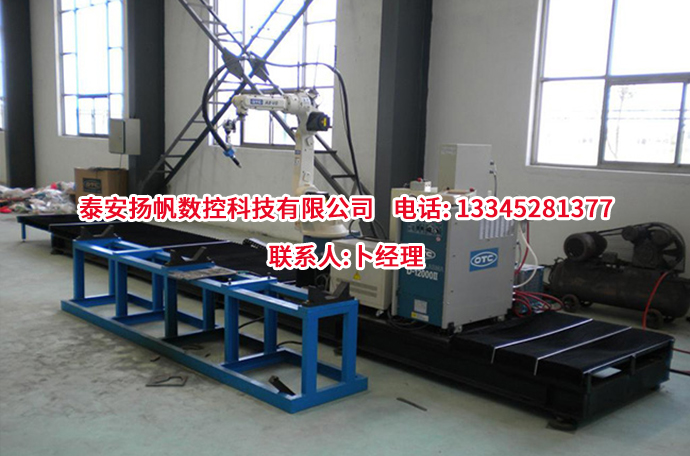

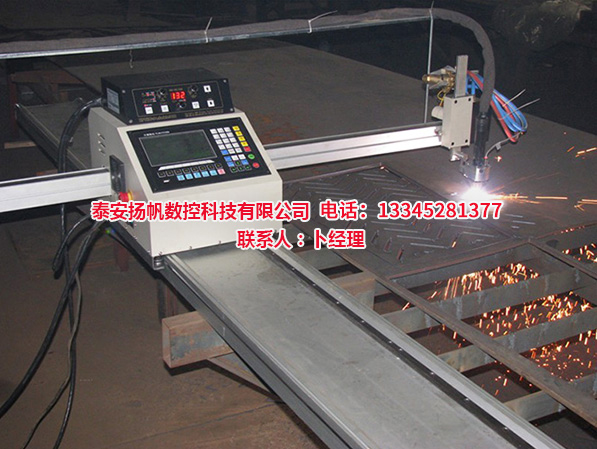

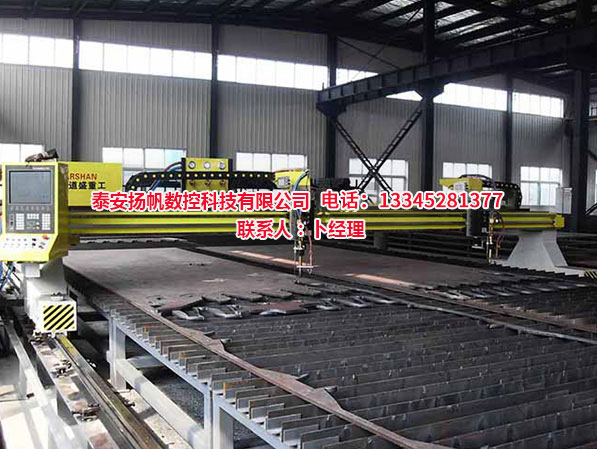

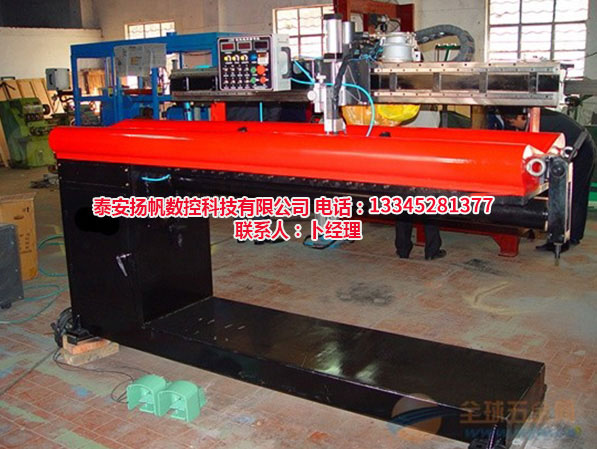

本公司為客戶供應(yīng)從焊接、切割、除塵及相關(guān)輔件等全流程的產(chǎn)品,公司配備一支經(jīng)驗(yàn)豐富的技術(shù)團(tuán)隊(duì),為您提供焊接設(shè)備,切割設(shè)備的售前售中售后服務(wù)。您有需求就來我們網(wǎng)站http://m.gouteli.cn聯(lián)系咨詢吧!

The company provides customers with products from welding, cutting, dust removal and related accessories. The company is equipped with an experienced technical team to provide you with pre-sale, mid-sale and after-sales services of welding equipment and cutting equipment. If you have any need, please come to our website http://m.gouteli.cn Contact us!

上一篇:焊接變位機(jī)使用中可能出現(xiàn)的機(jī)械故障

下一篇:數(shù)控焊接設(shè)備選購時(shí)考慮三方面